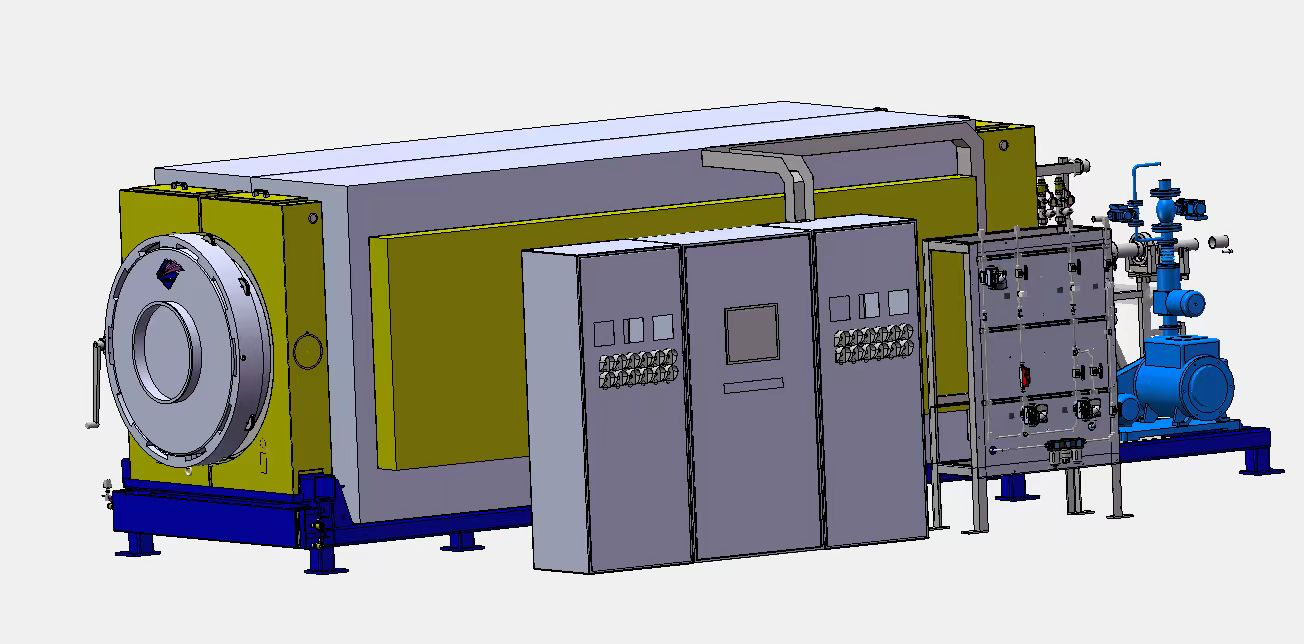

SiC Rotary Furnace

Keywords:

CEMENTED CARBIDE PRODUCTION

SiC Rotary Furnace

Features:

1. Large single batch production capacity and low energy consumption: filling rate ≥ 60%, up to 2 tons/batch or more

2. High utilization rate of silane: long contact time of silane gas and powder, full adsorption

3. high yield: silicon deposition and carbon coating process does not produce agglomeration, agglomeration and tar and other undesirable phenomena

4. Good uniformity of deposition and coating: local strong fluidization, uniform mixing of materials with the help of furnace rotation and material lift plate

5. Multi-function: silicon deposition and carbon coating are carried out continuously, and the finished product is released from the furnace.

6. high safety: fully enclosed operation, can completely replace the air

Technical parameters

|

Product Specifications |

CS-RGF4080 |

CS-RGF90250 |

CS-RGF120400 |

|

Effective Temperature Zone |

Φ400*800mm |

Φ900*2500mm |

Φ1200*4000mm |

|

Temperature Range |

500~900 ℃ |

500~900 ℃ |

500~900 ℃ |

|

Processing Gases |

SiH4, C2H2, N2 | SiH4, C2H2, N2 | SiH4, C2H2, N2 |

|

Porous Carbon Dosage |

25kg |

400kg |

800kg |

|

Batch Output ~ 48 hours |

50kg |

800kg |

1600kg |

Previous Page

Similar Products