Products

Product manual

Applications

• This furnace is applied in reducing Tungsten Oxide, Molybdenum Oxide and Cobalt Oxide powder into Tungsten, Mo. & Co. powder in H2 atmosphere.

Features

•Temperature Control

Adopt 3-phase to 2-phase transformer to meet the requirement of balanced power grid.

The furnace can handle temperature from 1400℃ to 2400℃.

Available for multiple ways of measuring temperature: infrared, thermometer, constant power.

•Temperature Uniformity

Adopted special structure design (DMF patent) to improve furnace temperature uniformity, and ensures that the temperature uniformity of any cross section of the furnace is within 10 °C. The peak temperature of any single tube does not exceed the set value by 20 °C.

•Safety

Gas-curtained or double door design can prevent air enter the hearth, and greatly improve the expected life of the graphite tube.

•Minimum Maintenance

DMF improved the furnace tube assembly structure, so that tubes can be easily replaced compared to traditional design.

•Automation

Auto-loading and unloading mechanism is available. Multiple methods of pushing boat available for choice, such as motor drive with variable frequency speed control, and cylinder with intermittent pushing.

Compact machine is available to match, expected to increase capacity by 20%.

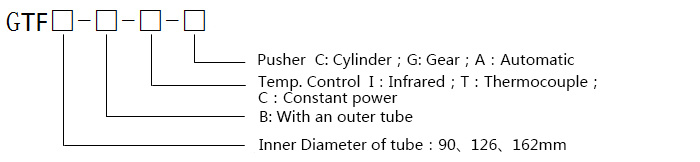

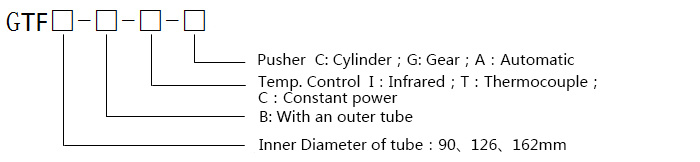

Model Coding Rules

Specification

|

Model |

Working Temp (℃) |

Dia. of tube (mm) |

Power (KVA) |

Capacity for WC (kg/h) |

Weight (kg) |

L * W * H (m) |

|

GTF90 |

2300 |

90 |

45 |

~10 |

~1200 |

3*1.0*1.6 |

|

GTF126 |

2300 |

126 |

100 |

~20 |

~2000 |

4.5*1.2*2 |

|

GTF162 |

2300 |

162 |

145 |

~35 |

~2500 |

5*1.4*2.2 |

MESSAGE

*Note: Please make sure to fill in the information accurately and maintain smooth communication. We will contact you as soon as possible