Products

Product manual

Applications

•The furnace is an ideal type to produce uniform and fine tungsten carbide powder, with capacity about 40kg/h. It can also be used to sinter cemented carbide in H2 atmosphere.

Features

•Overall Design

Boats are pushed ahead into the tunnel, DMF patented the double-door mechanism and boat transportation system. Equipped with emergency N2 in case of lack pressure.

•Automation

Equipped with PLC controlled automatic loading/unloading, weighing, densification, piling, covering of boats functions, the furnace continuously operates with high production efficiency.

•Easy Maintenance

The furnace chamber is made of corundum, and the Molybdenum filaments are hanged on two-side walls of the hearth outside the chamber, which makes it maintenance friendly.

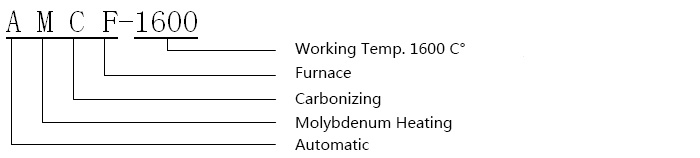

Model Coding Rules

Specification

|

Model |

Working Temp. (℃) |

Heating Zone (mm) |

Power (KVA) |

Capacity for WC (kg/h) |

Heating Element |

Weight (Ton) |

L * W * H (m) |

|

AMCF-1600 |

1550 |

2600/4500 |

110/250 |

40~80 |

Mo wire |

10~20 |

8(16) * 2.5(3) * 2 |

MESSAGE

Note: Please leave your contact information and our professionals will contact you as soon as possible!

*Note: Please make sure to fill in the information accurately and maintain smooth communication. We will contact you as soon as possible